Much to our relief Lightermans Yard is safely back at its home base having spent too long split up into car loads having been on the road, and then in different storage locations. Not that the team were inactive, we maintained monthly contact via Zoom as previous blog postings will testif.

Our most urgent task was to find out why, after a perfect set-up, we had operational problems on the day at the Portsmouth show last month. These were mostly track feed issues causing frequent stopping dispite track, stay-alive and loco wheel cleaning.

On reflection, and there's been plenty of time for that, is that we are a small group - sometimes very stretched at exhibitions, and we would welcome anyone interested in operating 2mm fine scale model trains, to come and join us. (conact Pete King: kingpete47@hotmail.co.uk).

We are also begining to think beyond Lightermans Yard, which has been a great and popular success at exhibitions. Perhaps now is the time to start thinking about building another 2mm scale layout?

The 'Yard' works because it can always be active with plenty of train movements; from arrivals to shunting and train formations to be picked up by refreshed locos. There can always be train activity even if we have to occasionally encourage an engine. Our focus this month was to try and establish why we had apparent problems with the layout. The only way to find out is to set up and run!

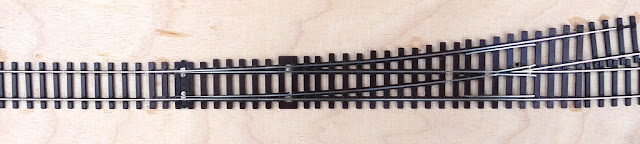

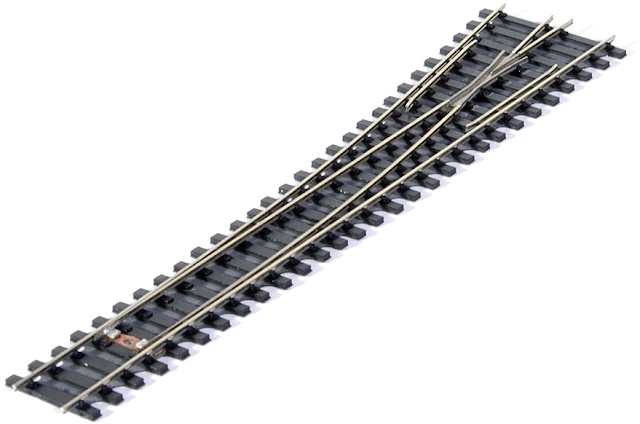

Recently announced the first of the new 2mm finescale point kits are now in 2mm Assocation Shop 1.

Alan has had a major hand in developing these kits with Finetrax. His comments are here; The base is a 3d print in resin. All the rails slide into chairs on the base.The crossing and switch rails are pre machined with no further work required other than trimming to length.

The tie bar is another 3d print that takes the ends of the switch rails. Locating pins and plates

Pre soldered to the rails locate in position.

The only other job required by the builder is to attach electrical feed wires.

Upon testing rolling stock passed through without hesitation.

The best thing since sliced bread?

You bet.

Currently the first kits available in the Association Shop 1 are right and left hand B7, (1-455 RH B7 and 1-456 LH B7 - priced at £19.00 each - illustrated instructions.

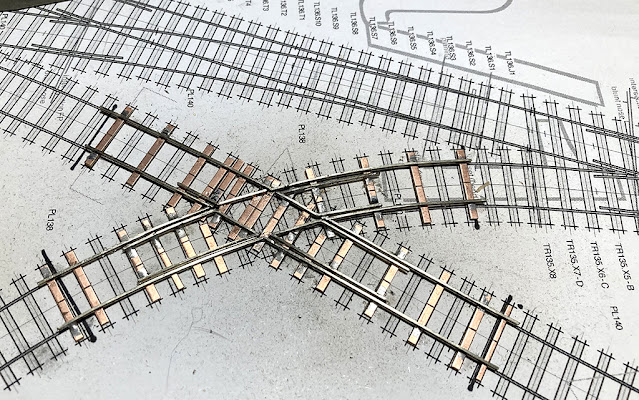

crossing detail below

Howard noted that Lightermans Yard gets a mention in Noel Leaver's new book "Advanced Modelling in N gauge" (and a photograph) on page 70 - Osbornsmodels)

Reflection on the past year(s) - mince pies and tea! Next meeting Sunday, 9th January 2022.

Meeting Room. rear of St Michael & All Angels. Church Hill, Wilmington, Dartford, Kent DA2 7EH