Another New Year arrives, and with it new resolutions too, some may be not so new being the same as for past new years, others may herald an actual start of a project, even if only in the mind, planning and researching, and living the dream.

But enough! Post the uncertanties and non events of the last three years, we are again able to meet face-to-face. Those of us who met in the virtual space of Zoom felt partly connected through talking heads, and happily shared images of work in progress. Nothing like a challenge as well to bring on an air of competition. So a happy and (2mm) fruitfull new year.

2023 brings us closer to deciding on the evential retirement of Lightermans Yard. Individual projects (Evercreech Junction and Brixham) are on-going, both are complex and large and need careful management to which other members of the group may be able to contribute. However, the sprit is there.

The track and traverser, the main subject for January - reconnecting the traverser to the main base boards.

Pete King ad Alan Smith soldering contacts on the replacement profesional grade DIN connector (as shown last month) which should be much more durable than the 'D' type currently used.

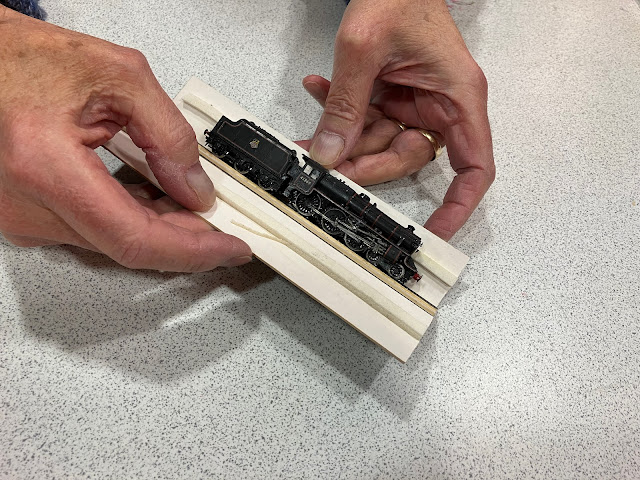

Signal box leavers for Pete King's Brixham layout. Operation of points will be manual from this set of levers.

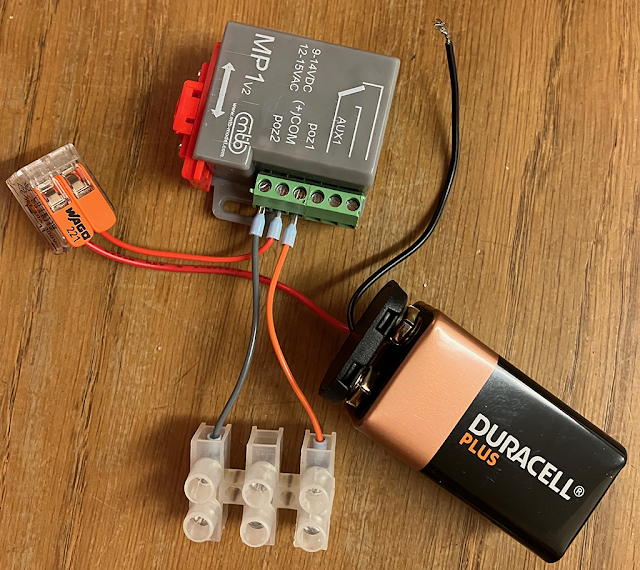

Howard showed a turntable destined for Evercreech Junction. The MERG turntable kit consists of a MERG kit (#79, £20.33 to MERG members), and a 12V stepper motor (RS 440-262) & a 250:1 reduction gearbox (RS 336-416). Mounted under a Peco N gauge turntable. This is an ex-demo piece and is donated to Evercreech Junction.

Howard also showed a digital caiper (below) made by USA company iGaging and is available in the UK from Wood Workers Workshop. The one shown here is the 4" version (£33.95 inc vat). Howard is very pleased with the his.

Next meeting 12 Febuary

The 2mm Kent and Essex Area Group meets on the second Sunday of

each month in St Michael's Church hall, Wilmington near Dartford in

Kent. Members come from both sides of the River Thames and from wider

afield.